1969 Chevrolet Corvette C3 Convertible

The owner of this Corvette has enjoyed and driven this vehicle around the world before eventually settling on becoming his daily driver whilst living in the U.S. However, when he shipped it down to Australia, the car was relegated to languish uncovered in general storage, which had led to significant wear and degradation over the years.

When we first saw the car it was sadly a barn find - partially disassembled by a previous shop, covered in dust and infested by rats. The convertible roof was not fitted during storage which resulted in further damage to the interior necessitating a complete teardown. During this process we found the fibreglass had numerous cracks throughout and nose cone damage that necessitated extensive fibreglass repairs. Thankfully, this area is one of Ken’s true specialities.

Upon further inspection we learned that the car had been in a T-bone accident in the U.S., resulting in the replacement of the right-hand side door and rear which were subject to a poor patch-up and not correctly aligned. Additionally, we discovered evidence of a rear-end collision that had been packed with body filler. Removing these old repairs was a necessary if not time-consuming and messy task.

We meticulously resurfaced and resealed the entire car after grinding it down, as nearly every corner of the vehicle exhibited some form of damage or wear and tear. We took great care to match and gap the entire vehicle, a surprisingly challenging endeavour due to the vehicle and doors' propensity to move. We adjusted everything to ensure that body lines remained true around the doors and bumpers for a seamless fit. We also smoothed out the firewall using flush rivets and added a plating on top for a gorgeous end result.

The small block Chev engine underwent substantial modifications including a stroker kit and Edelbrock Performer enhancements to push it up to 550hp. We upgraded everything in-house including the pistons, heads, camshaft, intake manifold, and carburettor paired with an electric distributor.

We also managed to retain the original side pipes for the customer, having the original cast alloy covers re-chromed before sinking our teeth into the electrics.

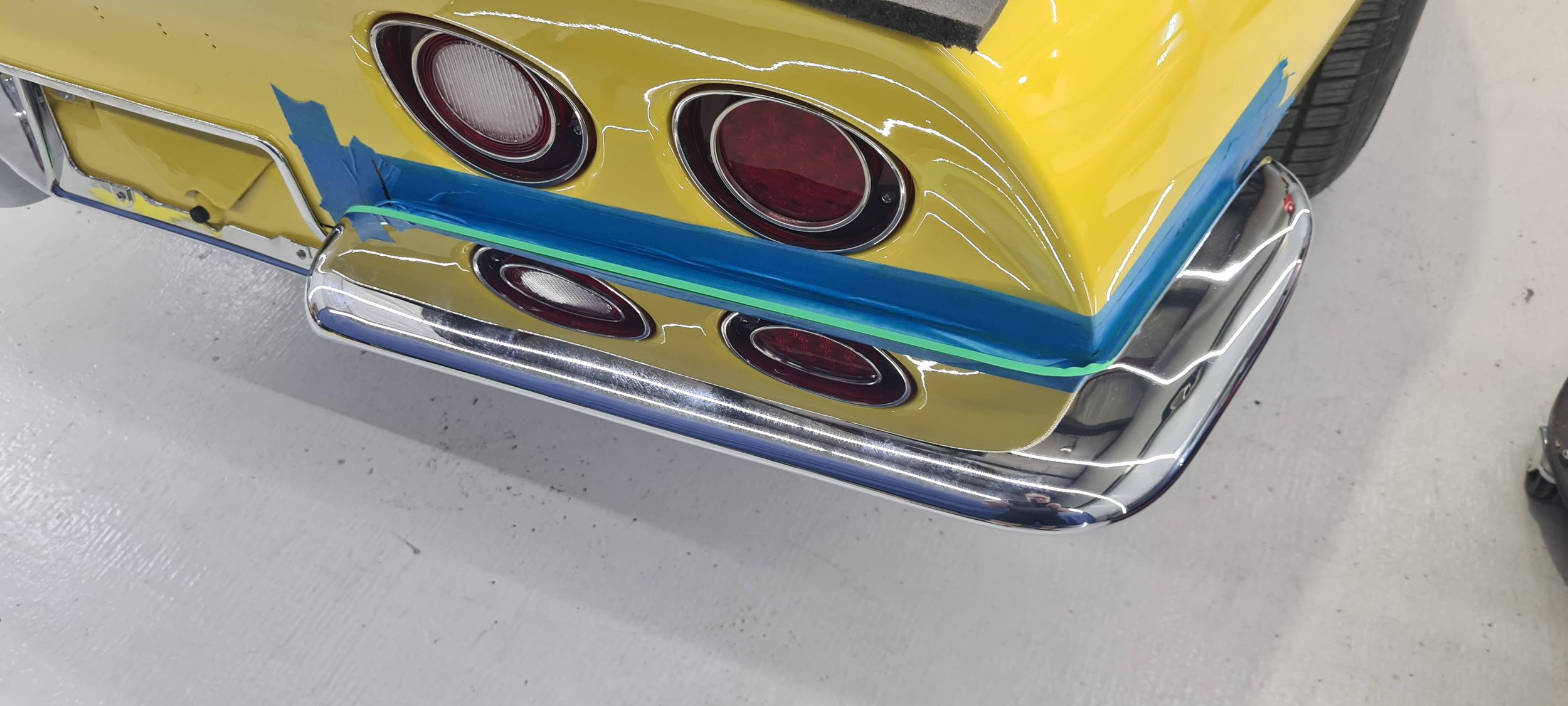

We wanted the headlights to keep that original flavour but with the performance and appeal of modern LEDs using a Holley RetroBright kit, and also upgraded the taillights to LED as well. A new wiring loom was installed throughout the build along with a new vacuum system. We ended up having to replace or repair virtually every part of the electrical system whilst preserving the original setup.

The car's original chassis had suffered badly from salt corrosion, the scars of which it had earned from its time spent driving in snowy states. To say it was in bad shape was an understatement, but our team completely restored it through extensive repairs and powder coated for longevity. We installed a completely new suspension and driveline, incorporating an independent rear suspension (IRS) rear end. This change shifted the car from transverse rear leaf springs to a far superior coilover setup which provided better street manners.

The customer also provided us with a steering rack that was… challenging. It required pretty extensive modifications and adjustments using cutting jigs and custom bracketry to get it to play ball. The supplied steering column also needed modifications to fit properly, but now performs like a dream.

We replaced all the brake and fuel lines as the original ones were rusted beyond repair. We used a race-style aluminium fuel line as a template and then had it replicated in mandrel-bent steel for strength. We then set about fitting a 6-pot front and 4-pot rear Brembo brake combo that makes the Corvette feel like it could fold in half on demand.

We were lucky enough to obtain a locally sourced hood which turned out to be a fantastic find that thankfully required a surprisingly small amount of adjustment to get it to fit beautifully. We then applied Ken's fiberglass expertise which resulted in an exceptional fit and finish.

The car's interior was sound deadened from front to back, and while the original chrome was retained, many missing brackets and such had to be hand-crafted. We also installed new glass throughout which sounds easy enough on paper, but we quickly discovered some unique challenges such as how a 1969 window mechanism differs almost imperceptibly from those manufactured 12 months earlier in 1968. We replaced the glove box, centre console, and carpets with new and repaired the cracked hard-lid on the back.

In contrast to many restoration projects where salvageable components are reused, this was a truly ground-up chassis restoration. Fitting the dashboard was a particularly difficult task, involving the careful alignment of three dash sections at the same time and in a certain order of steps to ensure a snug fit and prevent any protrusion from the centre.

The entire restoration project spanned nearly two years and involved extensive efforts to source and modify parts along the way. It was a labour of love for both the owner as well as our team, and one of the most satisfying projects we’ve worked on in recent years.

There is a reason why so many will baulk at the mere mention of a ground-up Corvette rebuild. The unique nature and angles of the vehicle, the fact that everything in very real terms moves as you work on it, means to do it right takes as much patience and feel as it does skill and know-how. We would relish the opportunity to build another.